- Rediscover Orchid Style

- On a mission to offer Orchid Style, the most stylish and eco-friendly flooring, we present new ORCHID+ design LVT flooring,

50 of our latest and finest designs featuring Wood, Stone and Design lines.

-

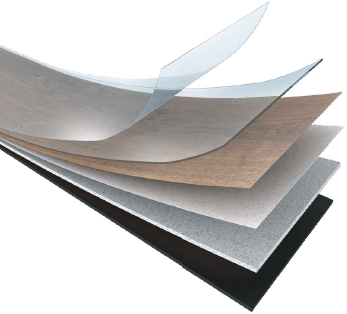

EPT™ Shield

- Safe and strong 2-fold LVT surface coating technology

- Anti-bacterial coating with superior

scratch-resistance

-

EMT™ Core

- Stable and eco-friendly LVT core technology

- Unique multi-layer structure with supreme

dimensional stability

Difference Specialties

-

- EPT™ Shield & EMT™ Core Technology

-

NOX Corporation, one of the world-largest LVT manufacturers, traces its roots to chemical engineering with expertise in core components of LVT flooring for more than 50 years. Its NOX EPT™ Shield & EMT™ Core technologies are the foundation of ORCHID+ innovation, providing the most stable and eco-friendly products.

-

- EPT™ Shield

-

⋅ Safe and strong 2-fold LVT surface shield technology

⋅ PU or Ceramic PU coating treatment [Anti-Bacterial] without

using Nano-silver [controversial to be harmful for human health]

⋅ Clear design protection layer

-

- EMT™ Core-5D

-

⋅ Stable and eco-friendly LVT core technology

⋅ 5-layered EMT™ Core structure for long-term dimensional stability

-

Additional Features

Diverse design and technical features are available upon request

-

- Surface Embossing

-

- ORCHID+ with 9 different surface embossing textures including natural Embossed-In-Register

-

I-03 Sand structure -

I-14 Wood structure -

I-17 Natural wood structure -

I-19 Rustic wood structure -

I-22 Wood structure -

I-25 Wood structure -

I-34 Stone structure -

I-35 Design wood structure -

I-37 Fabric structure

-

- Edge Type

-

- ORCHID+ can be supplied in 3 types of edges according to your request

-

Round Edge -

Bevel Edge -

Square Edge

-

- Continuous EIR (Embossed-In-Register)

-

-

- The first & only 'Continuous EIR (Embossed-ln-Register)' Technology

-

Technical Information

- Specifications

- Installation Guideline

- Maintenance

- Test Result

| Brand | Thickness [mm] | Wear Layer | Size [mm] | Pcs/Box | Sqm/Box |

|---|---|---|---|---|---|

| ORCHID+ | 2.5 | 0.20mm /0.55mm /0.70mm |

186 x 940 | 19 | 3.32 |

| 180 x 1,200 | 15 | 3.24 | |||

| 304.8 x 609.6 [12“ x 24“] | 18 | 3.34 | |||

| 152.4 x 914.4 [6“ x 36“] | 24 | 3.34 | |||

| 457.2 x 457.2 [18“ x 18“] | 16 | 3.34 | |||

| 457.2 x 914.4 [18“ x 36“] | 10 | 4.18 | |||

| 600 x 600 | 12 | 4.32 |

- Prior to installation, the subfloor must be heated for 14 days if heating is available, and if not, allow sufficient time to dry out completely.

- Room temperature must be maintained at 18˚C or higher before and during installation.

- The flooring must be allowed to acclimate in the room to be installed for a minimum of 24 hours and be stacked flat on the floor to avoid bending the floor.

- Prior to installation, please ensure that both color and lot# are the same.

- When installing ORCHID+, be sure to keep dust, dirt or foreign particles away from the locking strip.

- Regularly sweep floor to remove sand and grit that can scratch floor.

- For best results, use only water with a mop. Avoid flooding the floor with too much water.

- For heavily soiled areas, use a neutral ph balanced floor cleaner.

- Use caution when lifting boxes.

- Promptly remove any standing water to avoid slippage.

- Keep ORCHID+ on the flat surface to keep it from warping.

| Product Specification | Standard | ECOLAY+ |

|---|---|---|

| Surface Treatment (NOX EPT™) | ISO 22196 ASTM G21-15 | Anti-Bacterial / Anti-Fungi |

| Level of Use | ISO 10874 | 0.20mm: 22+ |

| 0.55mm: 23, 33, 42 | ||

| 0.70mm: 23, 34, 43 | ||

| Total Thickness | ISO 24346 | +0.13mm / -0.10mm |

| Wearlayer Thickness | ISO 24340 | +13% / - 10% |

| Weight (g/m2) | ISO 23997 | +13% / - 10% |

| Dimensional stability & Curling after exposure to heat | ISO 23999 | ≤0.10% |

| ≤2.0mm | ||

| Abrasion group | EN 660-2 | Class T |

| Castor Chair resistance | ISO 4918 | No damage |

| Squareness & Straightness | ISO 24342 | ≤400mm : ≤0.25mm |

| >400mm : ≤0.35mm | ||

| ASTM F2055 | ≤0.01in | |

| Residual Indentation | ISO 24343-1 | ≤0.1mm |

| Static Load Limit | ASTM F970 | ≤0.005 in @ 250psi min |

| Light Fastness | ISO 105-B02 | ≥ 6 |

| Slip resistance | EN 13893 | DS |

| DIN 51130 | R10 | |

| Resistance to Chemicals | ISO 26987 | No defects |

| Thermal Resistance | EN 12667 | 0.017 (m2K/W) |

| Fire Resistance | EN 13501-1 | Bfl-s1 |

| Body Voltage | EN 1815 | 2kV |

| Peel Resistance | ISO 24345 | More than 60N/50mm |

| Formaldehyde Group | EN 717-1 | E1 |

| VOC Emissions | IAC GOLD CERTIFIED / FLOOR SCORE CERTIFIED | Very low VOC |

- Get in touch with us

- For product brochures, samples or any questions.

We’re here to help.